In the pharmaceutical industry, ensuring the safety, sterility, and chemical stability of products is of utmost importance. The choice of packaging material is critical in pharma packaging. At C.L. Smith, we understand that using glass bottles packaging plays a vital role in meeting stringent pharmaceutical packaging standards. By leveraging our sister company, Silver Spur Corporation’s high-quality glass bottles, we are uniquely positioned to deliver the ideal cost-effective packaging solutions for sensitive products like vaccines and medications.

The Role of Glass in Pharmaceutical Packaging

Glass has long been a trusted material in pharmaceutical packaging, primarily due to its inert nature. Unlike plastic, glass does not leach chemicals into its contents, making it an excellent choice for preserving the integrity of medications. This inertness ensures that the active ingredients remain stable and effective over time. Additionally, the transparency of glass allows for easy visual inspection, ensuring that products are free from contaminants before they reach consumers. This visibility is crucial for quality control and patient safety. Glass packaging also provides excellent barrier properties, protecting medications from moisture and oxygen, which can degrade their efficacy. These attributes make glass an ideal choice for pharmaceutical applications, where maintaining product purity and safety is paramount.

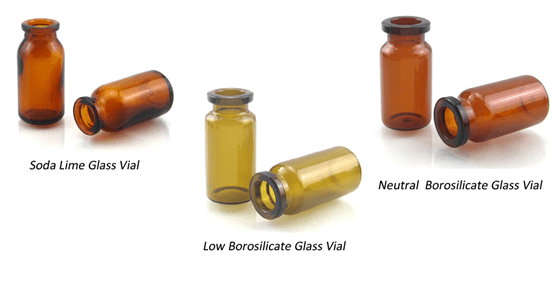

Types of Glass Used in Pharmaceutical Packaging

When it comes to pharmaceutical packaging, not all glass is created equal. There are three primary types of glass recognized in the industry: Type I, Type II, and Type III. Each type has unique properties that make it suitable for various pharmaceutical applications.

- Type I Glass: Known as borosilicate glass, Type I glass is highly resistant to thermal shock and chemical corrosion. This makes it ideal for packaging sensitive products, such as parenteral solutions, which require a high level of sterility and stability. C.L. Smith ensures that the glass bottles sourced from Silver Spur Corporation meet the rigorous standards associated with Type I glass.

- Type II Glass: This soda-lime glass undergoes a surface treatment to enhance its chemical resistance. While not as robust as Type I glass, Type II glass is suitable for products that are less sensitive but still require protection from moisture and air. At C.L. Smith, we recognize that Type II glass can be an economical choice for certain pharmaceutical applications without compromising safety.

- Type III Glass: Also made from soda-lime, Type III glass is the least resistant to chemical attack. It is often used for packaging non-injectable pharmaceuticals that do not require extensive stability. Although it does not meet the same rigorous standards as Type I and II glass, it is still a valuable option for many pharmaceutical products.

Why Glass is the Preferred Choice for Sensitive Products

Why Glass is the Preferred Choice for Sensitive Products

Glass is particularly favored for packaging vaccines and medications due to its inherent qualities:

- Chemical Resistance: Glass provides an impermeable barrier, protecting contents from external contaminants and ensuring product integrity throughout its shelf life. This resistance is crucial for maintaining the efficacy and safety of sensitive pharmaceuticals.

- Sterility: Glass can be sterilized through various methods, including autoclaving, making it ideal for products that require a high level of sterility, such as injectable drugs. This ensures that the packaging remains free from microbial contamination, safeguarding patient health.

- Regulatory Compliance: The pharmaceutical industry is heavily regulated, and glass packaging is often preferred because it can meet stringent regulatory requirements set by organizations like the FDA and EMA. Glass’s consistent performance and reliability help manufacturers comply with these rigorous standards.

- Sustainability: Glass is recyclable and can be reused without losing its integrity, aligning with the growing emphasis on sustainable practices in the pharmaceutical sector. Its recyclability reduces environmental impact and supports the industry’s move towards greener solutions.

These attributes make glass an ideal choice for sensitive products, ensuring they remain safe, effective, and compliant with regulatory standards throughout their lifecycle.

C.L. Smith & Silver Spur Corporation: Your Partner in Pharmaceutical Packaging

At C.L. Smith, we are committed to providing innovative packaging solutions that meet the highest standards of safety and efficacy. Our partnership with Silver Spur Corporation enables us to offer a comprehensive range of glass bottles that cater to the unique needs of the pharmaceutical industry.

By choosing C.L. Smith and Silver Spur Corporation, you can trust that your packaging will not only comply with industry standards but also ensure the safety and quality of your products. We understand the challenges faced by pharmaceutical manufacturers and are dedicated to supporting your success through reliable packaging solutions.

Partnering for Success in Pharmaceutical Packaging

Partnering for Success in Pharmaceutical Packaging

In an industry where precision and safety are important, glass bottles emerge as a superior choice for pharmaceutical packaging. With their chemical resistance, ability to maintain sterility, and compliance with regulatory standards, glass bottles from C.L. Smith and Silver Spur Corporation are ideal for safeguarding sensitive products like vaccines and medications. As we continue to innovate and adapt to the evolving needs of the pharmaceutical sector, we remain your trusted partner in achieving excellence in packaging.

For more information about our glass packaging solutions, contact C.L. Smith today and discover how we can help you meet your pharmaceutical packaging needs.

Comments are closed