C.L Smith is proud to be working with Inhance Technologies in packaging thymol-based disinfectants. The U.S. Environmental Protection Agency has recently approved Thymol as an ingredient to kill the coronavirus.

Background

Consumer Product companies’ interest in Thymol-based disinfectants is growing rapidly. Thymol, derived from the oil of various herbs including basil and thyme, is a natural, anti-microbial botanical. Because this plant-based component breaks down quickly, it’s less harmful to the environment than other chemical cleaners. Plus, the botanical oil kills germs and bacteria without strong chemicals or the harsh smell of bleach.

Because of its molecular composition, Thymol will readily permeate through conventional plastic packaging. The effective concentration of Thymol in a product formulation can be very low (often < 0.5%), so ensuring it remains active in the formulation – and not absorbed by the plastic container walls – is critical to maintaining product quality and integrity.

Protect Products, People, and Planet

There has been a surge in inquiries regarding packaging water-based Thymol formulations since the EPA approval. Many companies are bringing Thymol-based products to market to help fight coronavirus. Several factors should be taken into consideration when choosing packaging configurations for Thymol-based disinfectant products:

- Thymol readily is absorbed by plastics: Due to its molecular composition, Thymol is readily absorbed by conventional plastics used in packaging.

- Product loss prevention is critical: Since the Thymol content in any formulation is very low (<0.5%), virtually any product loss to package absorption (“scalping”) will quickly lead to loss of product efficacy, reduced shelf life, and dissatisfied customers.

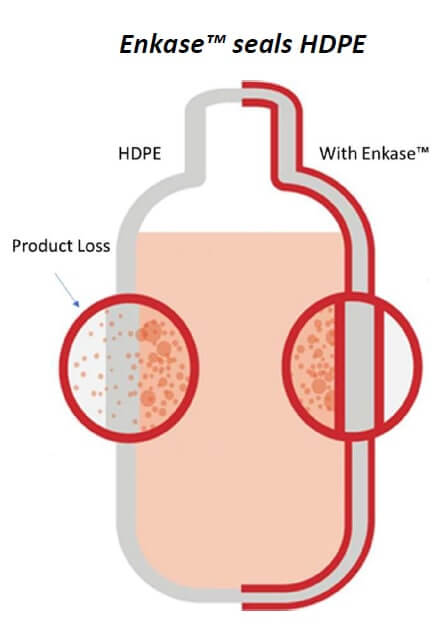

- Careful choice of package construction: Barrier plastics are often necessary to maintain formulation integrity. However, when conventional HDPE is in contact with a Thymol-containing formula, Thymol can readily be absorbed into the container walls, sprayer, seal or cap. As such, a 100% HDPE container, or multilayer container with HDPE on the inside layer, is not suitable.

- Enkase™ barrier technology is the best choice to prevent Thymol absorption: When HDPE is sealed with Enkase, the container walls, which are in direct contact with the formulation, inhibit the absorption of Thymol. Enkase works on any HDPE container, meaning that any packaging in your inventory can quickly become highly effective, yet environmentally friendly barrier packaging. Enkase also seals caps, sprayers, and other plastic components used in packaging.

Contact C.L. Smith today to learn more about the features of this barrier technology and packaging thymol based disinfectants. Our packaging consultants are available to assist you with your packaging needs and concerns.

Leave a Reply

You must be logged in to post a comment.