HARMONIZED WORKER SAFETY REGULATIONS

In the same manner that the US DOT, in an effort to facilitate global commerce, has largely harmonized the regulations concerning the transportation of hazardous materials in commerce in the US with the rest of the world, OSHA has adopted the first step in the harmonization of the hazard communication requirements for workers using hazardous chemicals in the conduct of their activities with a set of internationally recognized communication standards.

This international workplace chemical hazard analysis and communication system is known as GHS (Globally Harmonized System of Classification and Labeling of Chemicals). OSHA has adopted a final rule implementing this change with a currently published schedule of deadlines for chemical manufacturers, distributors and importers.

It is important for anyone involved with these activities to understand their responsibilities under the revised regulations and initiate a compliance program on schedule.

Impact of CHANGE REQUIREMENTS

The requirements of the change fall into three main areas:

1. Hazard Classification

2. Safety Data Sheets

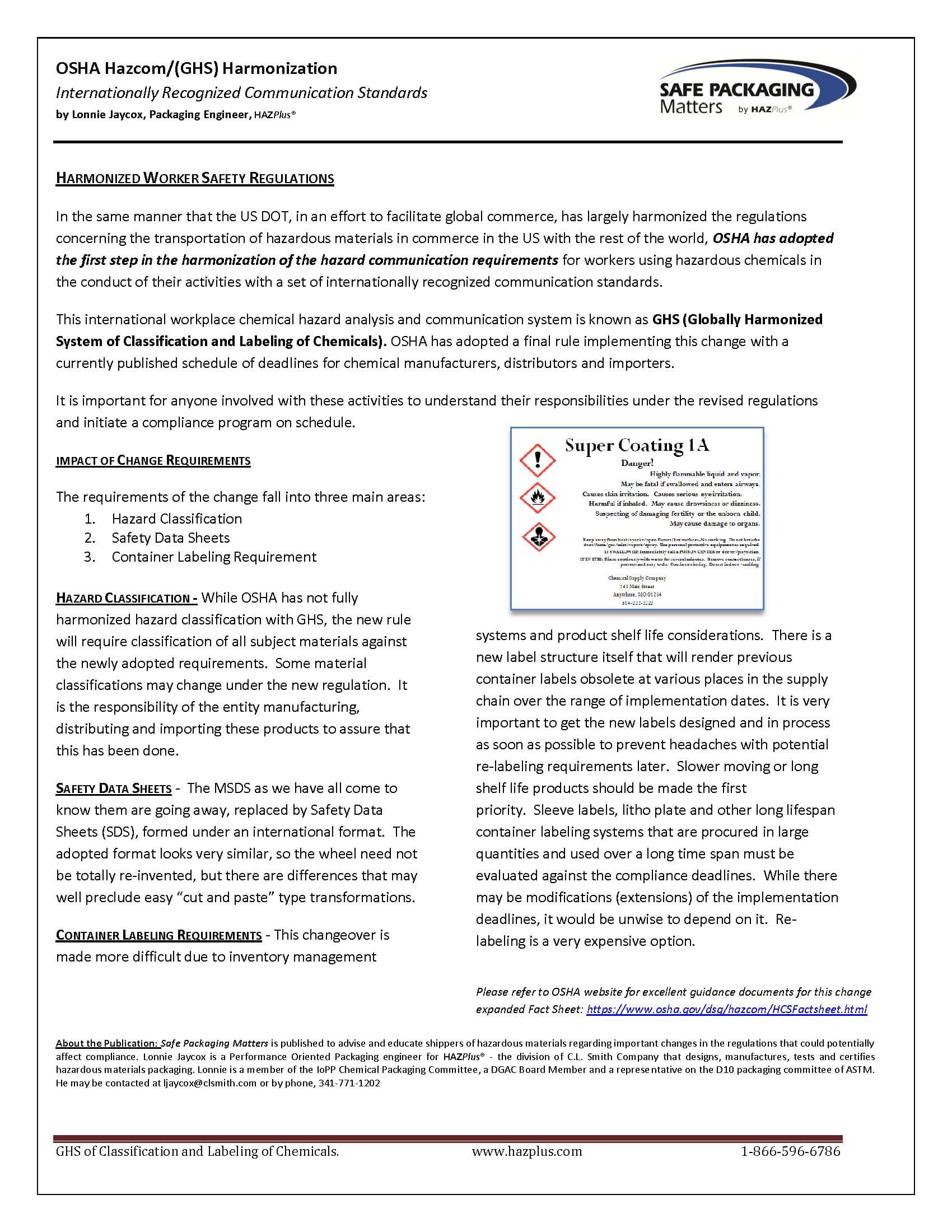

3. Container Labeling Requirement

HAZARD CLASSIFICATION

While OSHA has not fully harmonized hazard classification with GHS, the new rule will require classification of all subject materials against the newly adopted requirements. Some material classifications may change under the new regulation. It is the responsibility of the entity manufacturing, distributing and importing these products to assure that this has been done.

SAFETY DATA SHEETS

The MSDS as we have all come to know them are going away, replaced by Safety Data Sheets (SDS), formed under an international format. The adopted format looks very similar, so the wheel need not be totally re-invented, but there are differences that may well preclude easy “cut and paste” type transformations.

Container Labeling Requirements

This changeover is made more difficult due to inventory management systems and product shelf life considerations. There is a new label structure itself that will render previous container labels obsolete at various places in the supply chain over the range of implementation dates. It is very important to get the new labels designed and in process as soon as possible to prevent headaches with potential re-labeling requirements later. Slower moving or long shelf life products should be made the first priority. Sleeve labels, litho plate and other long lifespan container labeling systems that are procured in large quantities and used over a long time span must be evaluated against the compliance deadlines. While there may be modifications (extensions) of the implementation deadlines, it would be unwise to depend on it. Re-labeling is a very expensive option.

Please refer to OSHA website for excellent guidance documents for this change expanded Fact Sheet: https://www.osha.gov/dsg/hazcom/HCSFactsheet.html

Safe Packaging Matters is published to advise and educate shippers of hazardous materials regarding important changes in the regulations that could potentially affect compliance. Lonnie Jaycox is a Performance Oriented Packaging engineer for HAZPlus® – the division of C.L. Smith Company that designs, manufactures, tests and certifies hazardous materials packaging.

Lonnie is a member of the IoPP Chemical Packaging Committee, a DGAC Board Member and a representative on the D10 packaging committee of ASTM. He may be contacted at ljaycox@clsmith.com or by phone, 341-771-1202

Comments are closed