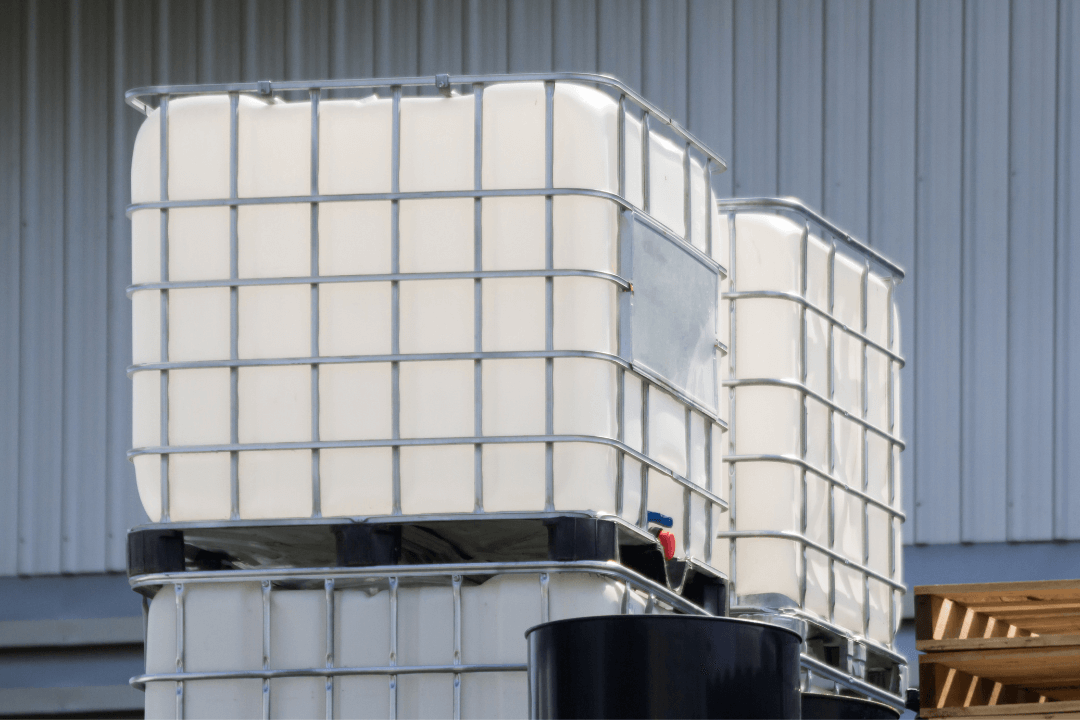

Selecting the right Intermediate Bulk Container (IBC) can be a game-changer for businesses looking to improve efficiency, reduce costs, and ensure product safety during storage and transportation. Whether you’re in the manufacturing, distribution, or logistics sector, choosing the right IBC involves balancing a range of factors, including the nature of your product, regulatory standards, and budget.

In this comprehensive guide, we’ll walk you through the key considerations for selecting the right IBCs, including factors such as product type, volume requirements, regulatory considerations, and budget constraints. By the end of this guide, you’ll have the knowledge to make an informed decision and choose the best IBC for your operations.

Table of Contents

- Understand Your Product Type & Requirements

- Determine Your Volume Requirements

- Choose the Right Material for Your IBC

- Regulatory Compliance & Safety

- Cost & Budget Considerations

- Sourcing Reliable Suppliers & Quality Assurance

- Making an Informed Decision

Understand Your Product Type & Requirements

The first step in selecting an IBC is to understand the type of product you’ll be storing or transporting. Different materials may require specific IBC designs and materials to ensure safety, durability, and compliance with regulations.

Key Considerations for Product Type:

- Liquids: Whether you’re transporting water, oils, or chemicals, liquid products may require IBCs made of certain materials to withstand corrosion or degradation. For instance, food-grade liquids need containers that are non-toxic and FDA-compliant.

- Powders: For dry bulk products such as powders or granular substances, an IBC with a vented lid may be necessary to avoid contamination or build-up of gases.

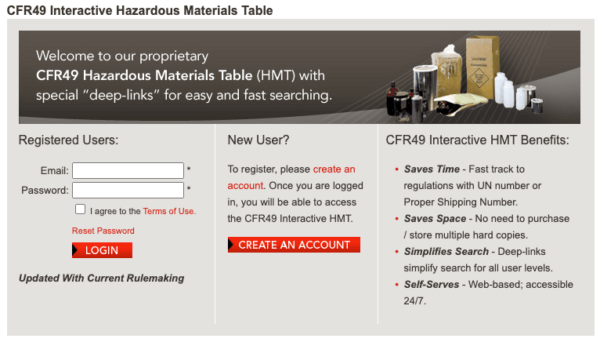

- Hazardous Materials: If you’re dealing with hazardous chemicals or flammable liquids, you’ll need an IBC that meets the necessary UN (United Nations) standards and provides adequate protection to prevent leaks and spills. C.L. Smith offers a free online interactive table for registered users to access shipping and regulatory details by entering a UN Number.

Register for a Complimentary Account

Register for a Complimentary Account

C.L. Smith offers a variety of IBC solutions that meet the demands of different industries, ensuring safe storage and transportation of all types of goods.

Determine Your Volume Requirements

Once you’ve identified your product type, the next important factor to consider is the volume you need to store or transport. IBCs are available in a wide range of sizes, typically from 275 gallons to 330 gallons, but they can also come in larger volumes depending on your needs.

Things to Consider:

- Operational Efficiency: Larger IBCs may be more cost-effective for high-volume needs, reducing the number of containers required to move the same amount of product.

- Space & Handling: If space is limited or if your staff handles the containers manually, smaller IBCs might be more appropriate for ease of use.

- Inventory Management: Be sure to evaluate your inventory turnover rates. If you have fast-moving products, opting for a slightly smaller IBC could help you optimize your storage space.

Choosing the right volume will depend on both your operational needs and your storage space. C.L. Smith has a wide array of IBC sizes that cater to both large-scale and smaller-scale operations.

Choose the Right Material for Your IBC

IBCs are available in several materials, each offering distinct advantages depending on your product and environment. Some common IBC materials include:

- Plastic (HDPE): A popular choice for non-hazardous liquids and food-grade materials. Plastic IBCs are lightweight, durable, and resistant to corrosion.

- Steel: Steel IBCs offer higher strength and are often used for transporting hazardous chemicals, as they provide extra protection against leaks and damage.

- Composite: Combining the benefits of plastic and steel, composite IBCs offer a sturdy exterior and a food-grade inner liner, suitable for both food products and chemicals.

- Wooden & Cardboard Liners: For dry goods, these options provide a lightweight, cost-effective solution for storage and transportation.

Understanding the materials your product requires can ensure that your IBC is both safe and cost-effective. Consult with the team at C.L. Smith to determine which material is best suited for your needs.

Regulatory Compliance & Safety

When selecting an IBC, ensuring that it complies with relevant regulations is crucial for both safety and legal compliance. Different industries and types of goods are governed by various standards that affect how IBCs must be constructed and labeled. Some key regulatory considerations include:

- UN Certification: If you transport hazardous materials, make sure the IBC is UN-certified to meet international shipping standards.

- FDA Compliance: If you’re transporting food-grade liquids or pharmaceuticals, FDA compliance is a must.

- ESR Standards: As environmental sustainability becomes increasingly important, adhering to Environmental Safety Regulations (ESR) is essential to reduce environmental impact and avoid potential fines.

C.L. Smith provides IBCs that meet or exceed regulatory standards, ensuring that your products are transported safely and in compliance with relevant laws.

Cost & Budget Considerations

Finally, your budget will play an important role in determining which IBCs are suitable for your business. While initial purchase costs are an obvious consideration, it’s important to also factor in the long-term expenses associated with maintenance, reconditioning, and disposal.

Tips for Managing Costs:

- Opt for Reusable IBCs: If you’re looking to reduce long-term costs, reusable IBCs are a great option. Their durability and reusability can make them a cost-effective solution, especially for businesses with high-volume needs.

- Explore IBC Reconditioning Services: Many companies, such as our sister company Southern Container, offer IBC reconditioning services, which allow you to reuse IBCs and meet environmental standards. This can significantly reduce costs while also addressing your sustainability goals.

At C.L. Smith, we can help guide you through your budget considerations and assist in sourcing the most cost-effective solutions for your operations.

Sourcing Reliable Suppliers & Quality Assurance

When choosing an IBC supplier, it’s important to ensure that you’re working with a trusted company that offers high-quality products and excellent customer support. Look for suppliers who offer clear certifications, product warranties, and after-sales services.

Things to Keep in Mind When Selecting a Supplier:

- Reputation & Experience: Choose a supplier with a strong track record in the industry. C.L. Smith has decades of experience helping businesses find the right packaging solutions.

- Customization Options: Your supplier should offer IBCs that can be customized to your needs, whether it’s adding additional fittings, custom liners, or labels.

- Customer Service & Support: A reliable supplier will assist with installation, maintenance, and troubleshooting as needed. C.L. Smith offers expert guidance and support at every stage of the process.

Making an Informed Decision

Selecting the right IBC is essential for optimizing your operations, ensuring product safety, and meeting your regulatory obligations. By considering your product type, volume, material, compliance needs, and budget, you can make an informed decision that aligns with your business requirements.

At C.L. Smith, we are dedicated to providing you with high-quality IBC solutions tailored to your needs. Furthermore, our sister company, Southern Container, a Novvia Group Company, offers IBC reconditioning services to help you meet ESR standards, reduce single-use plastics, and cut costs. Enjoy no-cost tote pick-up and storage to eliminate environmental liability, making your operations more efficient and sustainable.

Reach out to C.L. Smith today for expert advice and top-notch IBC solutions that will streamline your business operations.

Comments are closed