In today’s marketplace, ensuring the safety and integrity of your products is important. At C.L. Smith, we understand the critical role that packaging plays in maintaining product security, particularly in industries such as pharmaceuticals, food & beverage, and personal care. One essential element in this regard is the use of tamper-evident caps. This comprehensive guide will dive into the importance of these closures, how they function, and key considerations for selecting the right solution for your product.

In today’s marketplace, ensuring the safety and integrity of your products is important. At C.L. Smith, we understand the critical role that packaging plays in maintaining product security, particularly in industries such as pharmaceuticals, food & beverage, and personal care. One essential element in this regard is the use of tamper-evident caps. This comprehensive guide will dive into the importance of these closures, how they function, and key considerations for selecting the right solution for your product.

The Importance of Tamper-Evident Closures

Tamper-evident caps serve as a first line of defense against product tampering and contamination. These closures not only protect consumers but also enhance brand trust and compliance with industry regulations. For manufacturers, using tamper-evident technology can significantly reduce the risk of liability and ensure that products reach consumers in a safe condition.

At C.L. Smith, we prioritize your product safety by offering a range of tamper-evident closures designed to meet stringent industry standards. Our caps are tailored for various applications, providing peace of mind to both manufacturers and consumers.

How Tamper-Evident Caps Work

How Tamper-Evident Caps Work

Tamper-evident caps are designed to show visible signs of tampering, ensuring that any unauthorized access to the product is easily detectable. These closures typically incorporate features such as:

- Breakaway bands: These bands remain intact until the cap is removed, leaving behind evidence of tampering.

- Shrink bands: A heat-shrinkable sleeve is applied to the cap, making it difficult to remove without breaking the seal.

- Induction seals: These provide an airtight seal and indicate tampering if the seal is broken.

When choosing tamper-evident caps, it’s crucial to consider their compatibility with your bottle designs. At C.L. Smith, we can assist you in selecting the appropriate closure that aligns with your packaging requirements.

Key Considerations for Choosing Tamper-Evident Caps

Key Considerations for Choosing Tamper-Evident Caps

- Cap Sizing: The cap must fit securely on the bottle to maintain its tamper-evident features. Proper sizing not only prevents leakage but also ensures that the closure can effectively indicate tampering. C.L. Smith offers a variety of cap sizes to fit different container dimensions.

- Material Strength: The materials used for tamper-evident caps are essential for both durability and functionality. Options include plastics like polypropylene or high-density polyethylene, which are both robust and compliant with regulatory standards. At C.L. Smith, we can guide you in selecting materials that meet your product’s specific needs.

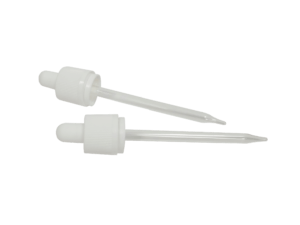

- Bottle Design Compatibility: Different bottles require specific types of caps to ensure functionality. For example, a dropper bottle will need a different closure compared to a wide-mouth container. C.L. Smith’s expertise in packaging solutions ensures that you can find the right fit for any design.

- Regulatory Compliance: Different industries have specific regulations regarding tamper-evident packaging. It’s vital to ensure that your caps comply with all relevant standards. C.L. Smith’s tamper-evident solutions are designed to meet or exceed these industry requirements.

Real-World Examples of Successful Implementations

Real-World Examples of Successful Implementations

Many brands have successfully implemented tamper-evident closures to enhance consumer trust and product safety. For instance, major pharmaceutical companies often use breakaway caps to protect their medicines, ensuring that consumers receive safe products. Similarly, leading food & beverage brands use shrink bands to prevent contamination and reassure customers that their products have not been tampered with.

At C.L. Smith, we are proud to support manufacturers in these industries by providing innovative tamper-evident solutions that enhance product security and compliance.

Securing Your Products with Confidence

Choosing the right tamper-evident caps is crucial for manufacturers focused on ensuring product safety and compliance. At C.L. Smith, we are dedicated to providing high-quality closures that meet the diverse needs of your products. By considering factors such as cap sizing, material strength, and regulatory compliance, you can enhance consumer trust and significantly reduce the risk of product tampering.

For more information about our tamper-evident cap solutions, please reach out to C.L. Smith. Together, we can secure the integrity of your products and provide consumers with the assurance they deserve.

Comments are closed