Artwork guidelines, tips for successful silk-screening & pricing guidelines for decorating from C.L. Smith. Contact us with questions and sample requests.

Artwork Guidelines

- Production-ready positives are preferred; however, our staff artist can produce positives from almost any stage. In this case, each label must be quoted separately.

- All positives must be right reading emulsion up.

- Art boards must be 600 DPI or greater.

- If camera ready art is not available or the artwork is less than 600 DPI, art charges will be quoted after the label is reviewed.

- Any revision costs involved will be the responsibility of the customer.

- If artwork was prepared on a computer, we can work from a 3 1/2″ disk, Macintosh format. Please send a black & white copy for comparison. Any fonts used and TIFF or PICT files must be included.

Tips for Successful Silk-Screening

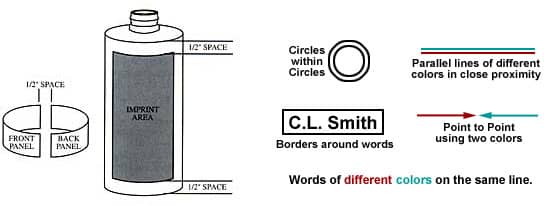

- Allow 1/2″ from the base and top of the shoulder for the printing process. On a cylinder or oval bottle, allow at least 1/2″ for the front and back panel making sure all printing is away from the bottle seams.

- Avoid very small type. 6-point type will not reproduce well.

- Avoid the following designs in multicolor printing:

Pricing Guidelines for Decorating (Oval Cylinder)

Uniform Product Codes

The Uniform Product Code Counsel states: A “Simple Scan” of a Bar Code is not sufficient; all parameters vital to Bar Code quality must be measured to determine that they are within specification. With our Quick Check 500 UPC Barcode Verifier we have implemented a quality assurance program to reproduce only the finest UPC symbols. Our verifying program not only determines if the code will scan, but also tells us in detailed lab reports how to improve scanability.

- We prefer to purchase all UPC film masters.

- 100% magnification symbols are recommended and bars should be printed horizontally.

- Space required for 100 MAG symbol is 1 1/2″ x 1 1/16″