Packaging in the 21st century is being driven by advances in material science, the adoption of circular economy principles, and practical case studies. These advances demonstrate a shift towards sustainability that is being driven at the consumer level. C.L. Smith is dedicated to providing adaptive strategies for their customers to help reduce the environmental impact of their packaging.

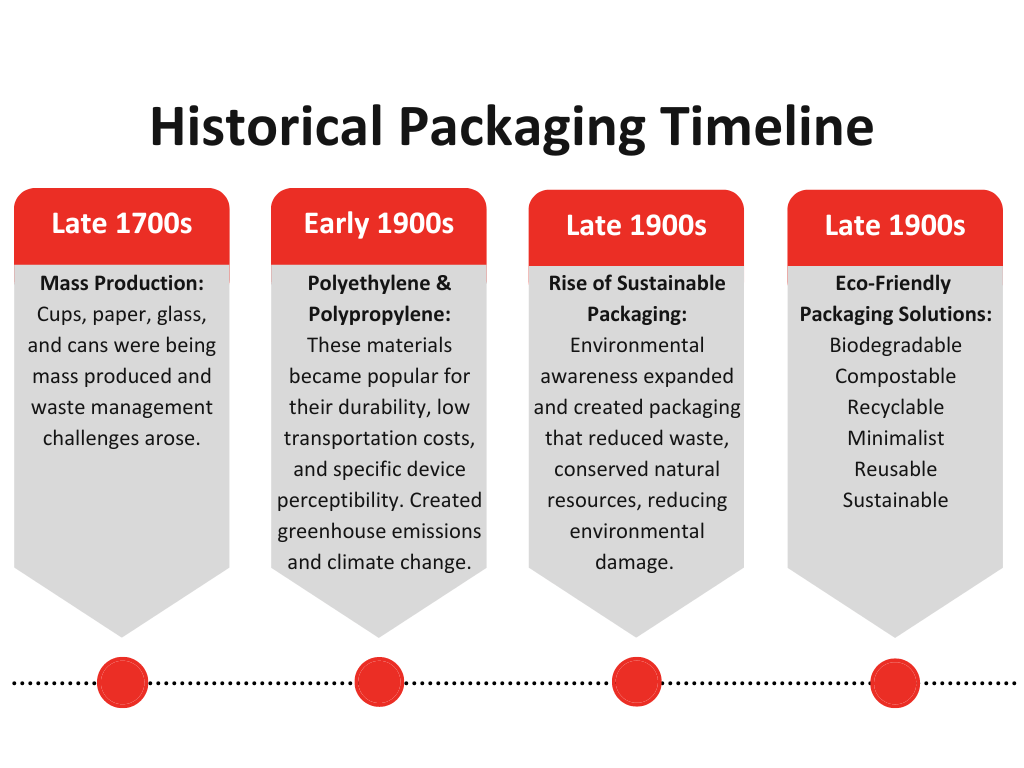

Historical Development

Industrial Revolution (Late 1700s)

Mass Production: This era saw the mass production of materials like cups, paper, glass, and cans. While this innovation facilitated widespread accessibility, it also introduced significant waste management challenges and concerns over resource origins.

Plastic Revolution (Early 1900s)

Polyethylene & Polypropylene: These plastics became the preferred choice for packaging due to their durability, low transportation costs, and specific device perceptibly. However, their production has significantly contributed to greenhouse gas emissions and climate change.

Rise of Sustainable Packaging (Late 1900s)

Urgent Need: Growing environmental consciousness spurred the development of packaging solutions aimed at reducing waste, conserving resources, and minimizing environmental damage.

Eco-Friendly Packaging Solutions (Late 1900s)

- Biodegradable Packaging: Made from materials like sugarcane and cornstarch, these packages can decay without harming the environment.

- Composable Packaging: Designed to break down into natural resources in production facilities.

- Recyclable Packaging: Engineered to be re-manufactured into new products post-use.

- Minimalist Packaging: Uses minimal materials to reduce waste.

- Reusable Packaging: Offers financial benefits to businesses and convenience to consumers by reducing waste.

- Sustainable Materials: Plant-based fibers such as bamboo, bagasse, and sprout-based packaging are increasingly used.

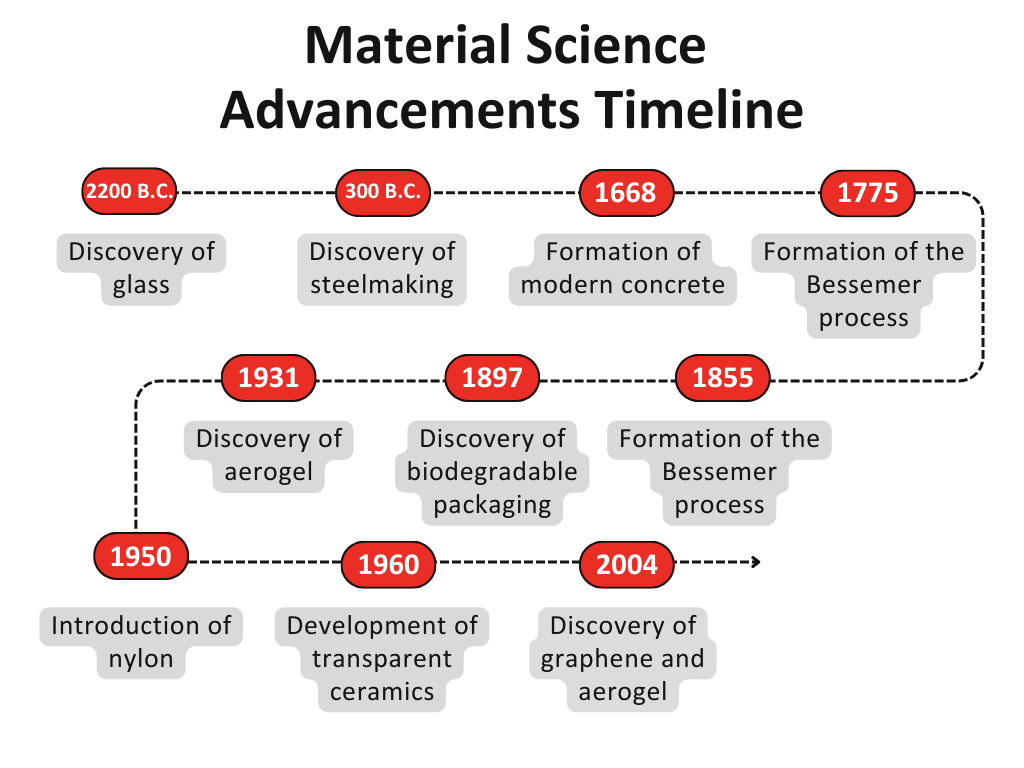

Material Science Advancements

Advancements in packaging were enabled by the development of material science:

- 2200 B.C.: Discovery of glass

- 300 B.C.: Discovery of steel making

- 1668: Discovery of microscopy

- 1775: Formation of modern concrete

- 1855: Formation of the Bessemer process

- 1897: Discovery of biodegradable packaging

- 1931: Discovery of aerogel

- 1950: Introduction of nylon, the first synthetic fiber, by DuPont

- 1960: Development of transparent ceramics

- 2004: Discovery of graphene and aerogel

Circular Economy Principles

The circular economy aims to maintain materials and products in use for as long as possible, reducing waste and environmental impact. It operates on three key principles:

- Design Out Waste & Pollution: Products are designed to minimize waste and pollution from the outset.

- Keep Products & Materials in Use: Maximizing the lifecycle of products and materials through reuse, repair, and recycling.

- Regenerate Natural Systems: Enhancing environmental health by regenerating natural resources.

C.L. Smith’s Commitment to Sustainability

C.L. Smith demonstrates a proactive approach to sustainability through various initiatives:

- Reducing Carbon Footprint: By minimizing energy consumption and waste production.

- Reducing Emissions: Focusing on reducing particulate noise and greenhouse gases.

- Recycling Programs: Implementing recycling programs through our sister company, Southern Container.

- Corporate Social Responsibility: Making sustainable purchasing decisions, raising awareness, conducting sustainability assessments, supporting local communities, and encouraging employee engagement.

Comments are closed