When transporting hazardous materials, failure to use compliant packaging can have serious consequences from environmental and property damage to even loss of life.

Aside from the safety hazards associated with any potential leakage or spills, there are associated civil penalties that a manufacturer or distributor can face when hazardous products are not properly packaged:

- The daily maximum fine for a typical hazmat shipping violation is $89,678.

- In the event of a violation that results in death, serious illness, severe injury, or substantial property damage is $209,249 per day.

In addition to having the proper compliant packaging, any employee who is in contact with hazardous materials in the workplace is required to have hazmat compliance training as required by 49 CFR 172.704. Failure to do so can result in a daily fine of up to $540 per employee.

Who governs hazmat packaging?

It is important to understand that there are several governing bodies of hazardous materials transport & packaging depending upon the method of transport. Each with their own standards & regulations for compliance, as well as penalties.

The United States Department of Transportation, DOT, delivers the world’s leading transportation system, serving the American people & economy through the safe, efficient, sustainable, and equitable movement of people & goods.

IATA, the International Air Transport Association, represents and serves airlines with advocacy and global standards for safety, security, and efficiency.

ADR and RID are the Agreements Concerning the International Carriage of Dangerous goods by Rail (RID) and by Road (ADR) from the United Nations.

The IMDG Code is the international code for maritime transport of dangerous goods in packaged form to enhance & harmonize the safe carriage of dangerous goods and prevent pollution to the environment.

What types of materials are hazardous?

There are a variety of materials that are considered hazardous and pose a significant safety risk during transportation such as medicine, chemicals, explosives, flammables, toxins, and corrosive substances in liquid, solid, or gas state. The US Department of Transportation provides a list of common hazardous materials:

- Aerosol Spray

- Airbags & Airbag Inflators

- Alcohols (rubbing & high proof spirits)

- Ammunition & Gun Powders

- Bleaches

- Camping Equipment (stoves, kerosene lanterns)

- Car Batteries

- Carbon Dioxide Canisters & Cylinders

- Consumer Electronics with Lithium Batteries

- Dry Ice

- Essential Oils

- Fertilizer Compounds & Ammonium Nitrate Fertilizers

- Fire Extinguishers

- Fireworks (Consumer & Novelty)

- Fragrances

- Fuels

- Fuel-Powered Equipment Containing Fuel

- Hand Sanitizer

- Inks

- Insecticides & Pest Control Products

- Lighters & Matches

- Lithium Batteries, Including Portable Chargers & Power Banks

- Mercury & Articles that Contain Mercury

- Nail Polish & Remover

- Oxygen & Scuba Tanks

- Paints, Thinners & Removers

- Refrigerant Gases (Liquid Nitrogen or Carbon Dioxide)

- Smoke Detectors

- Swimming Pool Chemicals

- Wood Treatment Products

If there is any confusion as to the classification of a substance being hazardous, always check the Safety Data Sheet (SDS) that is prepared by the manufacturer. The shipper is always responsible for understanding if the hazardous products are compatible with the packaging and following the proper regulations to ensure compliance of the shipment.

Communication & Packaging of Hazardous Materials

A key component of hazardous material packaging is labeling, and communication of the contents contained. This is based on the classification criteria of the substance or product and levels of risk. The three levels of risk are Packaging Group 1 (Very Dangerous Goods), Packaging Group 2 (Moderately Dangerous Goods), and Packaging Group 3 (Substances with a Lower Degree of Danger). The substance classifications are:

- Class 1: Explosive substances and articles

- Class 2: Gases

- Class 3: Flammable liquids

- Class 4.1: Flammable solids, self-reactive substances and solid desensitized explosive substances.

- Class 4.2: Substances which may undergo spontaneous ignition

- Class 4.3: Substances which, in contact with water, give off flammable gases

- Class 5.1: Oxidizing substances

- Class 5.2: Organic peroxides

- Class 6.1: Toxic substances

- Class 6.2: Infectious substances

- Class 7: Radioactive substances

- Class 8: Corrosive substances

- Class 9: Miscellaneous hazardous materials and articles

How do I classify my hazardous material?

The Safety Data Sheet contains all the information needed such as the properties of each chemical; the physical, health, and environmental hazards; protective measures; and safety precautions for handling, storing, and transporting the hazardous material. It should also include the UN Number associated with the classification of the product for the proper packaging.

How do I know which hazardous material packaging to use?

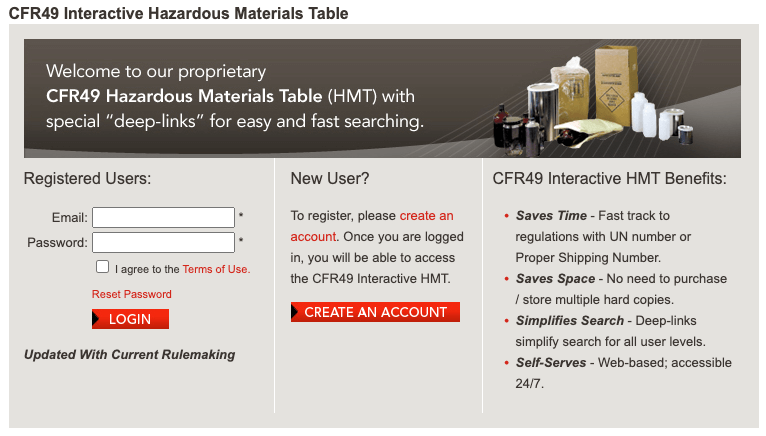

Once the associated UN number is located from the SDS the shipper must use the CFR 49 DOT HAZMAT Table to identify the packaging requirements for that classified product or substance.

To assist customers, C.L. Smith has developed a free online interactive table that allows registered users to input the UN Number and pull up the proper shipping name, hazard class or division, identification number, packing group, label codes, special provisions, packaging requirements, quantity limitations, and vessel stowage details linked back to regulatory rules for reference.

Register for a Complimentary Account

Common Mistakes

The world of hazardous material packaging and handling can be confusing, especially to someone with little or no hazmat experience. The most common mistakes are often incorrect labeling, being unaware that a product or substance is hazardous, lack of knowledge on how to handle a specific substance, and a general unawareness of packaging requirements based on mode of transport. Another key consideration that can be overlooked is who to call or what to do in case of an emergency.

Benefits of Working with a Partner in Hazardous Material Packaging

Many companies decide to work with a 3rd party to ensure full compliance in packaging, employee training, and peace of mind. Having access to industry experts who understand the complexity and requirements of hazardous material shipping and packaging can cut costs, save time, avoid spills, accidents, legal ramifications and even lives.

HAZPlus, the hazardous materials packaging division of C.L. Smith, is the preferred vendor when it comes to safe and compliant packaging. They offer a diverse portfolio of stock, ready to ship, UN-rated packaging solutions as well as an in-house testing facility for custom UN-rated packaging solutions. As an additional value-add, they offer complimentary hazardous material training & refreshers for their customers as well as a variety of online training offerings on demand.

The HAZPlus Testing Facility in St. Louis, MO

Comments are closed